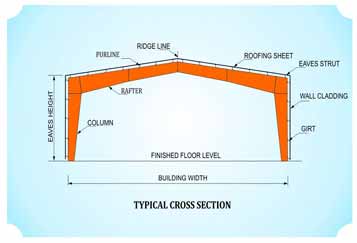

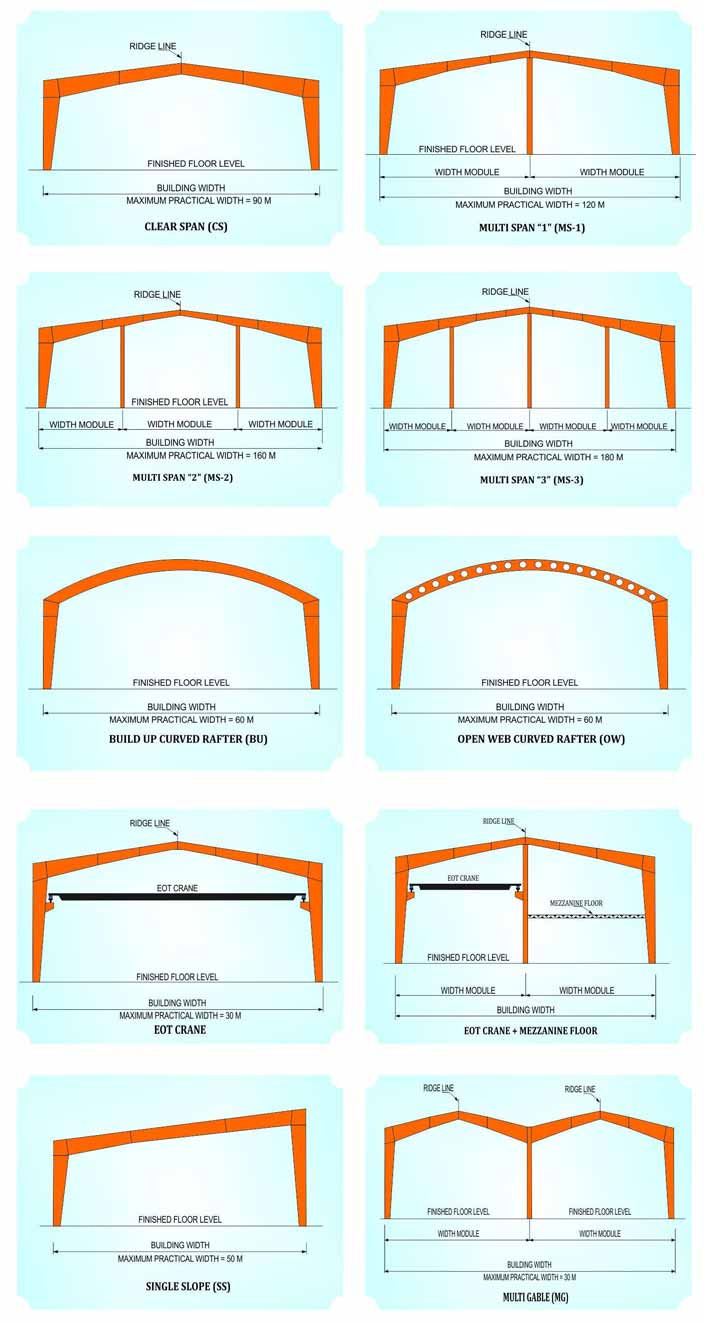

Pre Engineered Buildings can be as unique as customer needs. Pre Engineered buildings are the state of art steel solution to develop an efficient and cost effective infrastructure.

PEB's offer ultimate design flexibility and an extremely short construction time. PEB's are supplied to site as fully finished product as structure. Only bolting connection required at site.

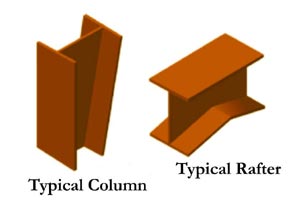

Steel Plates with minimum yield strength of 245 Mpa to 345 Mpa shall be used for Primary members. Shop Painting to a minimum DFT of 25 microns primed for all buildup sections. SM Star shall design based on building parameters and customer requirements. Typical Rafter and Typical Column as shown below.

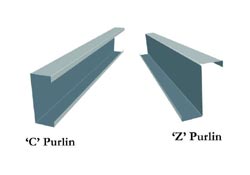

'Z' and 'C Cold formed Purlins and Girts shall be used to a average thickness of 1.6mm, 1.8 mm, 2 mm, 2.3 mm, 2.5 mm, 2.8 mm & 3 mm. Shop Painting to a minimum DFT of 25 microns primed for all Secondary members. CR steel as per IS:513 / HR Steel as per IS: 1076 materials with yield strength 245Mpa and 345 Mpa shall be used for Cold form sections.